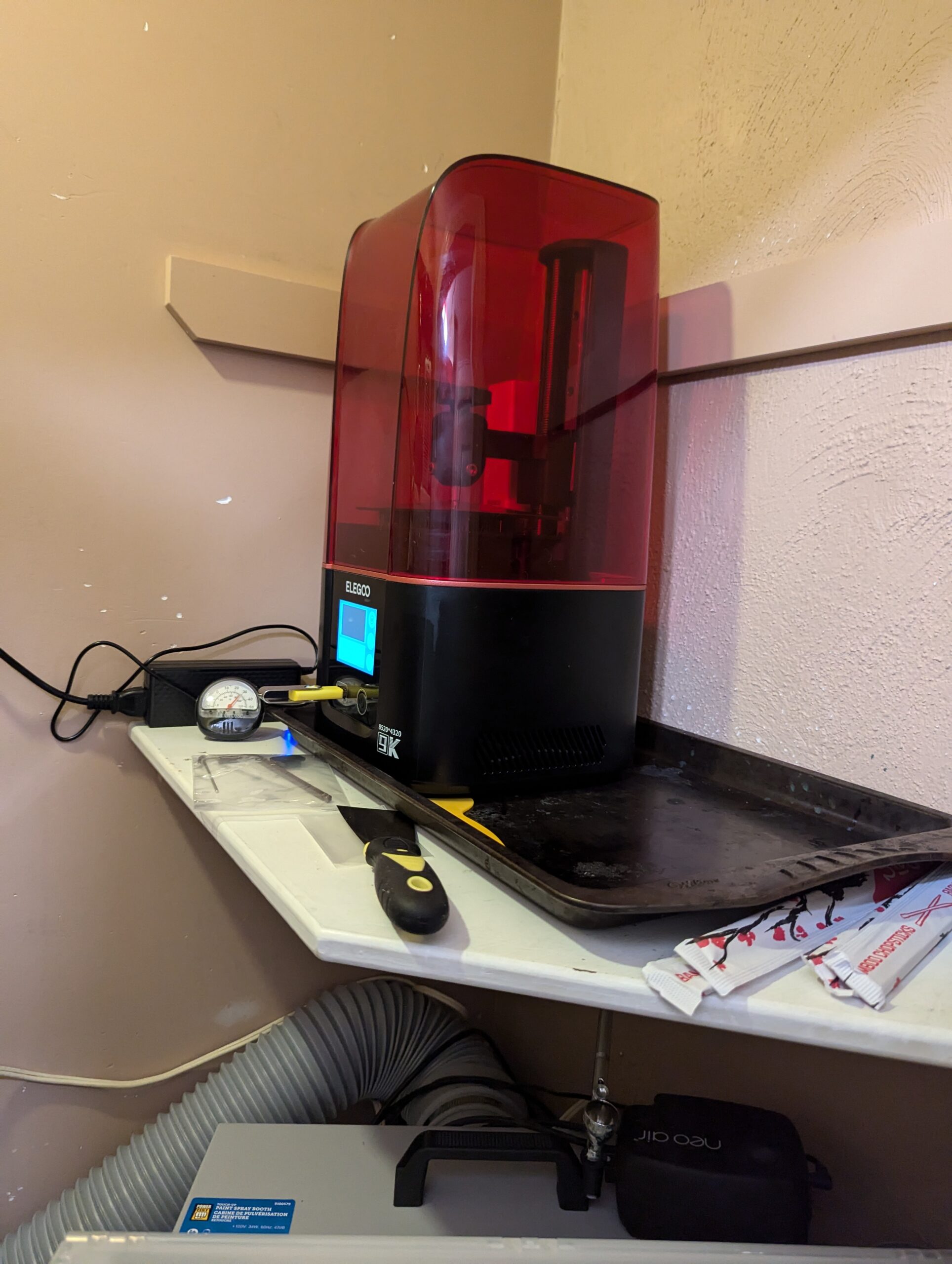

I broke down and ordered a Mars 4 this month. It arrived last week and I have been putting it through its paces. There has been much learning and adjustment. This post is about the setup I’ve created to print safely and consistently. I’m not touching on things like validation prints or resin viscosity or any of the usual weird nerd shit. I’ll say that I benefited greatly from Once In A Six Side’s comprehensive guide on YouTube, and from Peachy’s first-timer vid.

The challenges I faced were;

1. I have a 750sqft condo from a late 70s construction. Space is really, really at a premium.

2. Because my heating is radiator instead of forced-air, windows will both lose heat and freeze over during our colder months.

On the other hand, the advantages I had were;

1. Concrete construction and radiators with thermostats means heat in the unit is pretty consistent.

2. I really do own the place, so I can fuck around with infrastructure if I really need to.

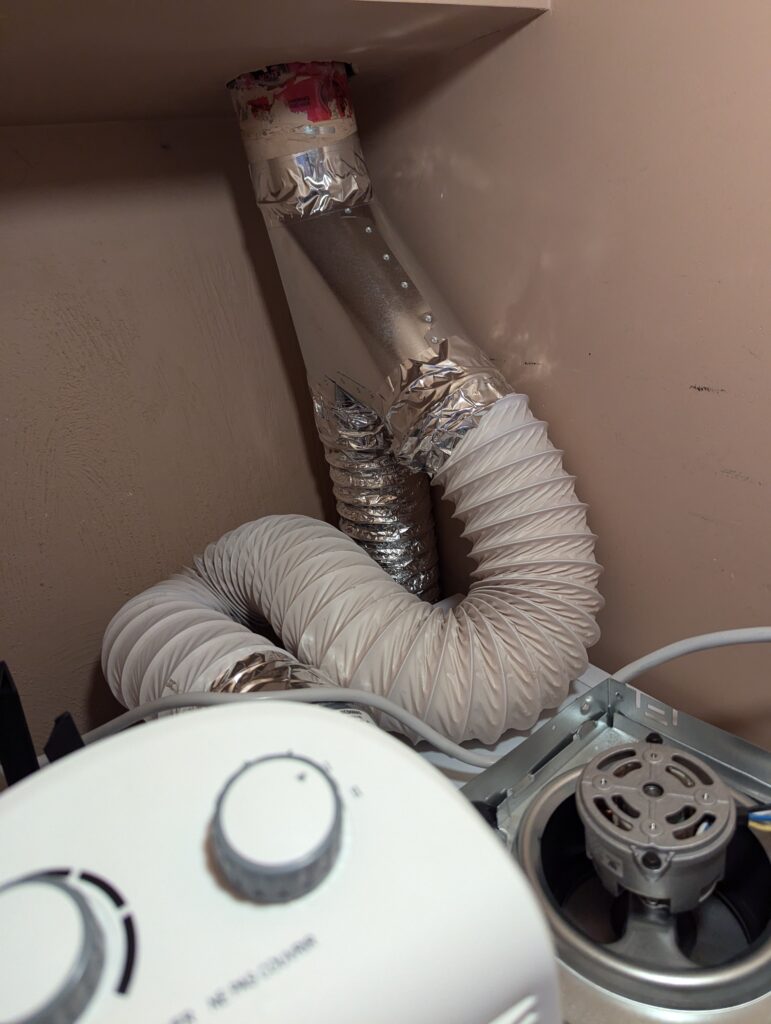

Here’s the solution I finally hit on, after considering and discarding several other ideas like the second-best I had, which was “buy a grow tent to block UV in and fumes out, vent it to a small window that I have very carefully sealed shut and heavily insulated, and add a couple of backdraft vents to prevent -40C winter air from intruding.” Instead, I took advantage of my unit’s independent dryer venting. Now, this came with some caveats. I didn’t want dryer air blowing lint all over my printer, and I didn’t want my printer scenting my laundry with resin.

I bought a 4″ Y-joint, a backdraft damper, and some high quality duct tape. That gave my dryer a vapour-protected straight shot to the exterior vent, like it had before. I then bought some more flex ducting and a cheap 50cuft/min bathroom fan (which came with its own backdraft damper built in) and tied that into the Y joint. Now both my venting solution and dryer exhaust pretty independently of each other and can both vent at the same time. The bathroom fan runs nonstop and 50cuft/min recycles all the air in the laundry closet in about 3 minutes. I can smell resin vapour when I pull the hood off the printer when a print is finished, so I know I can smell it- but with the fan running there’s not even a hint of it outside the closet and it’s faint inside while printing. I’ve also got a heater, electric and fan-driven, to maintain the 25-30C temperatures the resin likes. It takes tweak or two, sometimes, when the weather changes or the dryer’s on, but it’s powerful enough to keep the resin warm even through the venting, and it works a lot better than my initial abortive attempt with a brewer’s belt.

As a bonus, my airbrush- which similarly needs venting even in winter- can also vent to the bathroom fan. It’s significantly better than just venting outside.